On Monday, while everyone was out snapping up those post-holiday bargains, we went down to the boat to get in another afternoon of work. On the way, we dropped off the port starter at Joe's Auto Electric, which is actually run by Pete, Joe's son (or grandson). Joe's mother checked us in and mentioned how winter was great time of year for jobs like ours because Pete doesn't charge as much in the winter. That's always good news.

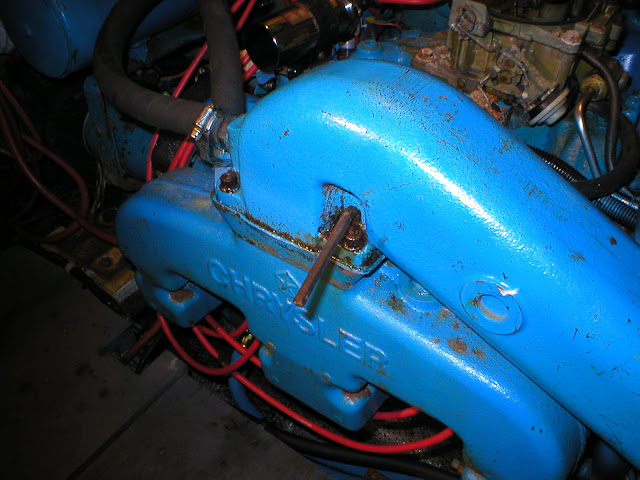

The issue we're trying to deal with now is checking the v-drive oil cooler for obstructions. That is really only accessible with the heat exchanger still off. We tried applying some heat but the hose wouldn't budge. We couldn't get too wild with the heat gun because the oil cooler had lots of old, tacked-on wiring in front of it. Here's the jumble of old wiring.

We can't stand this kind of sloppy wiring. We were going to have to leave the large red battery cables as they are but the other wiring (horn, battery charger, aft bilge pump, etc.) needs to be cleaned up.

Our preferred method for making connections like this is to use a terminal strip. New boats never use this method of connection but we like to because it is versatile and easy to troubleshoot. If properly installed with the connections coated in electrlydic grease, it poses no safety hazard and will last forever, unlike the modular connectors that are used on most newer boats today.

We mounted a 12-post terminal strip on a deck support and began cutting away all the old wring and reconnecting everything properly. Here's the terminal strip before we began wiring.

Even the terminal strip has a back story. Bill liberated this one and several others years ago from a 1960 35-ft. Chris~Craft Constellation that was going to be scrapped. It's been stored in our miscellaneous boat parts box even since and now it's going back in to service.

As usual, this little re-wiring job left us with lots of garbage, much of which should never have been put in there in the first place. We also found a wire that had pulled loose from the engine wiring harness. It appears to be a ground but we reconnected it while we were down there.

With the wiring cleaned up, we'll be able to tackle getting that hose off the inlet to the V-drive oil cooler so we can see of there is any sea grass and other junk partially obstructing it. That hose is 1-1/2" ID wire-reinforced hose, truly nasty stuff to work with. It has probably been there since the boat was built so pulling the hose off to inspect the oil cooler inlet may pose a challenge.

But, what the hell. It's winter and getting things done on the boat is fun.

This blog is about our experiences enjoying and maintaining our 1980 Silverton 34C powerboat.

Monday, December 26, 2011

Saturday, December 24, 2011

We've gone just about far enough

There comes a time when we realize that we've dismantled just about enough and we think we reached that point today. The heat exchangers are back from being boiled out and repaired. We primed them and applied two coats of blue Rustoleum engine paint. Two of the hose necks - one on each heat exchanger - needed repair and that was taken care of by Frank at the Auto Radiator Hospital.

With the heat exchangers removed, we now had access to the port starter. It seems to be working OK but last fall, the starboard starter acted up (worn brushes) and we had it rebuilt. Might as well take the port starter out and have it rebuilt, too. We couldn't get the two mounting bolts off with our existing wrenches (no room for a socket), so that meant a trip to Sears for a 9/16" wrench with a nice six-point end. With that, the bolts came out fairly quickly and we were able to lug this heavy old starter up onto the deck.

This week we'll take the starter to Joe's Auto Electric in Cromwell, CT. Don't laugh. Joe's is just like Frank at the Radiator Hospital. These old guys know how to repair marine equipment and they don't charge a lot. Actually, Joe was replaced by his son some years ago, but he still does a good job.

With the port starer out, we took a good look at the wiring for the windlass battery. Pretty shabby, so I guess we'll rip all that out and start over again. You have to love that corroded old 15-amp fuse in the ceramic holder. Strangely enough, it actually worked.

Along with all the things we're doing in the engine space this winter, Frances asked for better lighting in her galley. There's a nice little shelf that runs above the counter tops and we found some LED strip lights that should mount there pretty easily. The strip is 37 inches long and contains 90 LEDs. Here's what it looks like:

And turned on, it looks like Frances will have all the light she needs.

The lights come from superbrightleds.com and they cost about $22 for a 37 inch length. We bought two to cover all of the galley workspace. We'll be looking for more applications after we install these. They are very bright and the Admiral is thinking of lightening up the head space with LEDs like these as well.

It's Christmas Eve, so we'll enjoy the holiday and be back next weekend.

Happy Holidays & Healthy, Happy New Year to all.

With the heat exchangers removed, we now had access to the port starter. It seems to be working OK but last fall, the starboard starter acted up (worn brushes) and we had it rebuilt. Might as well take the port starter out and have it rebuilt, too. We couldn't get the two mounting bolts off with our existing wrenches (no room for a socket), so that meant a trip to Sears for a 9/16" wrench with a nice six-point end. With that, the bolts came out fairly quickly and we were able to lug this heavy old starter up onto the deck.

This week we'll take the starter to Joe's Auto Electric in Cromwell, CT. Don't laugh. Joe's is just like Frank at the Radiator Hospital. These old guys know how to repair marine equipment and they don't charge a lot. Actually, Joe was replaced by his son some years ago, but he still does a good job.

With the port starer out, we took a good look at the wiring for the windlass battery. Pretty shabby, so I guess we'll rip all that out and start over again. You have to love that corroded old 15-amp fuse in the ceramic holder. Strangely enough, it actually worked.

Along with all the things we're doing in the engine space this winter, Frances asked for better lighting in her galley. There's a nice little shelf that runs above the counter tops and we found some LED strip lights that should mount there pretty easily. The strip is 37 inches long and contains 90 LEDs. Here's what it looks like:

And turned on, it looks like Frances will have all the light she needs.

The lights come from superbrightleds.com and they cost about $22 for a 37 inch length. We bought two to cover all of the galley workspace. We'll be looking for more applications after we install these. They are very bright and the Admiral is thinking of lightening up the head space with LEDs like these as well.

It's Christmas Eve, so we'll enjoy the holiday and be back next weekend.

Happy Holidays & Healthy, Happy New Year to all.

Sunday, December 11, 2011

Pack'in heat

This was our weekend to remove the two heat exchangers from the engines so they can be boiled out and pressure tested. We do keep our trusty Colt .380 Mustang nearby when we're working on the boat during the winter, but to get five old hoses off from each of the two heat exchangers, we needed a different type of gun.

This heat gun (courtesy of Frances' late father) is one of the best tools we own and we use it regularly, particularly when coaxing new hoses on or old hoses off. Nothing works like heat and when used properly, this heat gun always does the job. We used it on its high setting to heat up the old hose connections on the heat exchangers and each hose came off with a minimum of effort, leaving all but one copper fitting undamaged. This doesn't always happen when you try to pry the hoses off with screwdriver.

Removing these things is at best a sloppy job since the bottom section holds lots of raw water (pink antifreeze at this time of year) and the upper section or surge tank was at least half full of green engine antifreeze. Once the hoses come off, it all goes in the bilge, flows to the rear of the boat and out the garboard drain. Yes, we caught the antifreeze in a bucket and disposed of it properly.

The engines look strange without the heat exchangers but now we'll have clearance behind the engines to do some cleanup and rewiring.

Here are what these things look like disconnected. We found that the zincs in each exchanger had been plugged with some kind of white caulk. In other words, there was no zinc on either side but there certainly will be when we reinstall them.

These Sen-Dure heat exchangers cost about $800 each when new, so we'll take good care of these old ones. We did note that someone had tried to solder a new fitting on the bottom of the starboard tank. Whoever that was, they didn't do a very good job and the copper tubing disintegrated as we removed the hose.

We're hoping that Frank at the Radiator Hospital will be able to repair that fitting properly. We'll find out tomorrow when we deliver these things to him. We're also delivering two other heat exchangers that come from our friend Rob's Luhrs. Might as well save some gas and time and do all four in one trip.

While we're reconditioning the cooling systems, we decided to add coolant recovery tanks to each heat exchanger. The "tanks" are really just plastic bottles that capture the coolant that overflows from the surge tanks when the engines are hot and then allow it to siphon back into the surge tanks when the engines cool. That keeps the surge tanks full all the time. These two coolant recovery tanks were quite hard to find, strangely enough, but we did locate a pair from a Sen-Dure dealer in Alabama. $29.00 each seemed quite reasonable given that they'll keep that hot coolant from drooling into the bilge while we're underway.

Before we left the boatyard on Sunday afternoon, we had to check out the boats and the river. The Connecticut River freezes often during the winter and it's necessary to put lines around the pilings (called spiles in this neck of the woods) to keep them from floating away if the ice pulls them out. It was a nice calm afternoon to get started on that job.

This winter, the boatyard is storing more than 220 boats, the most they have ever had before. Our best guess is that when money isn't as readily available as it was three or four years ago, there's value in storing at a place that allows you to work on your boat. The boats aren't small ones either. This Choy Lee is 50 feet long.

Sailboaters have also found this good place to store. This one is actually in the driveway.

Some boat owners like to create a nice dry workshop over their boat so they can work in relative comfort.

We've had a boat here for 24 years, and it still looks odd to see the docks empty. All of those docks will be coming out of the water too over the next two weeks.

With all the boats finally out of the water, it's time for the holiday decorations. Looks good to us.

Saturday, December 3, 2011

Winter 2012 begins

The weather has continued to be great and we took advantage of it on Saturday to take down the bimini top. That involves removing the 12 side curtain sections, passing them down to the deck and them loading them in the car. Definitely a two-person job. Some cold winter weekend, we'll lay them out on the living room floor and clean the plastic windows.

With the top down, we installed the bridge cover. It's certainly a nice thing to have to protect the bridge over the winter in the shed.

The October 29-30 snow storm that blacked out so many homes in Connecticut caught us with the boat still in the water. By the time we got to it, about a foot of wet snow had accumulated on the boat and the weight on the top of the bimini bent one of the three supporting frames. We'll replace the bent frame but it is just one more thing on our list that we didn't expect.

We have a number of things that we want to do this winter to bring the maintenance up to where we know what has and what has not been replaced or rebuilt. That involves replacing all the fuel lines (that is done) and also both carbs. The carbs are ready to go on but we're holding off on that until the exhaust risers are replaced. Those parts have been ordered. While we're down there with the carbs off, it's an ideal time to also remove the heat exchangers and have them boiled out. Again, we have no idea when this was last done, if it ever was. Might as well do it, while we can get at them. This week we talked to Frank Proto, Jr., owner of the Auto Radiator Hospital in East Hartford, who will boil them out and reseal them for $75.00 each. Frank did a heat exchanger for us years ago and it turned out perfectly so he's our guy. Nice how these old businesses still exist and that they don't charge and arm and leg.

These heat exchangers each have five hose connections and since these are a little different from the ones we have owned before, we took a few minutes to map out the water flows. These heat exchangers cool both the block and the exhaust manifold.

We know you're probably laughing at our drawing but it will be handy when we have to reassemble these thing.

Frank suggested that I also flush out the transmission oil coolers. "You'll find lots of junk in them," he told us. He's probably right. The transmission coolers are the first thing the water encounters after it leaves the sea water pumps.

Lots of hoses to disconnect when these things come off.

With the top down, we installed the bridge cover. It's certainly a nice thing to have to protect the bridge over the winter in the shed.

The October 29-30 snow storm that blacked out so many homes in Connecticut caught us with the boat still in the water. By the time we got to it, about a foot of wet snow had accumulated on the boat and the weight on the top of the bimini bent one of the three supporting frames. We'll replace the bent frame but it is just one more thing on our list that we didn't expect.

We have a number of things that we want to do this winter to bring the maintenance up to where we know what has and what has not been replaced or rebuilt. That involves replacing all the fuel lines (that is done) and also both carbs. The carbs are ready to go on but we're holding off on that until the exhaust risers are replaced. Those parts have been ordered. While we're down there with the carbs off, it's an ideal time to also remove the heat exchangers and have them boiled out. Again, we have no idea when this was last done, if it ever was. Might as well do it, while we can get at them. This week we talked to Frank Proto, Jr., owner of the Auto Radiator Hospital in East Hartford, who will boil them out and reseal them for $75.00 each. Frank did a heat exchanger for us years ago and it turned out perfectly so he's our guy. Nice how these old businesses still exist and that they don't charge and arm and leg.

These heat exchangers each have five hose connections and since these are a little different from the ones we have owned before, we took a few minutes to map out the water flows. These heat exchangers cool both the block and the exhaust manifold.

We know you're probably laughing at our drawing but it will be handy when we have to reassemble these thing.

Frank suggested that I also flush out the transmission oil coolers. "You'll find lots of junk in them," he told us. He's probably right. The transmission coolers are the first thing the water encounters after it leaves the sea water pumps.

Lots of hoses to disconnect when these things come off.

The boat next to us in the shed is this winter is owned by Rob, an old friend, who is always in the same shed as we are during the winter. Rob has a 34 ft. Luhrs with 454 Crusaders and he is also planning on changing his exhaust risers and refurbish his heat exchangers. We suggested that we both use Frank at the Auto Radiator Hospital and Rob thought that was a great idea. We volunteered to deliver the heat exchangers and pick them up, since we are close to East Hartford. Rob is fast, and in no time, his heat exchangers were in the back of our station wagon. Next weekend, we'll remove ours and then it's off to Frank in East Hartford.

We used to ski during the winter months but this is much more fun.

Saturday, November 19, 2011

Allen, our favorite wrench

While we haven't been updating our blog as often as we should, we have made progress on our winter list of things to do on the boat. We began by putting everything away, bringing stuff home and finding a place to store it all for the winter. Last weekend we scraped all the old crud out of the bilge spaces and used our shop vac to suck up all the stuff that had collected down there over the past 30 years. Oh yeah, there were a number of old screws, nuts, bolts and washers that had been lost over the years that got sucked up too.

We also replaced the fuel lines from the tank to each engine and that was surprisingly easy.

We're going to replace both of the old Quadrajet carbs with new Edelbrock 1409 carbs and we ordered and received the first one. The Edelbrock 1409 is a square bore carb and the old Quadrajets mounted on a Chrysler spread bore intake manifolds, so the new carbs require an adapter and obviously another gasket. Here's the adpater:

The new 1409 carb doesn't provide a vacuum fitting for the PCV hose but the adapter does. That's the brass fitting you can see at the back of the adapter.

The 1409 is really beautifully made, in fact, 100% made in America. We'll probably have to play around to make the throttle linkage fit the new carb just right, but that's half the fun. The new carb has an electric choke so we can forget about the problems we used to have with the thermostatic chokes on the old Quadrajets.

We'll install the new carbs after after we take care of replacing the exhaust risers on both engines, since we have no idea of when that was done last. No sense in installing a new carb and then trying to wrestle the old risers up and over it.

Here's the starboard engine before we started. We have v-drives so the engines face aft.

While we're down here taking things apart, we might as well remove the heat exchangers (the blue cylinders mounted at the back of the engine) and have them boiled out and re-sealed by a local radiator shop. They both work fine but why not have them reconditioned while we have such good access to them? We don't want to do this again for a long time!

The risers are mounted on adapters that mate them to the Chrysler exhaust manifolds. Each riser is fastened down with four Allen head bolts. Why Allen head, we'll never know. We've lost sleep thinking about how we'll get these bolts out without breaking one off or bending an Allen wrench. On each riser, the aft bolt is partially covered. Cute. Whoever designed there manifolds should be made to live in our bilge for a week.

We began by soaking each bolt with penetrating oil that in our experience never really works, but it was worth a try. We began with the easiest ones, the inside bolts on the inboard starboard manifold. Since we could actually see them, they seemed like a good place to see just how difficult this was going to be.

The first two actually came out, although not without a lot of help. That's an ordinary Allen wrench. It is the only thing that would fit in that spot.

The crud you see around that rusty old bolt is actually penetrating oil. This time, the penetrating oil worked. With the bolts on the starboard inside manifold out, we tackled the bolts on the outside starboard manifold, which is very close to the water tank. Not much room to move in there. Note the paper towel stuffed between the manifold and the valve cover? That was to trap the Allen wrench in case we dropped it. As we get older, we get smarter.

As luck would have it, that one came out too, as did the aft bolt, which was done completely by "feel."

It was getting cold in the shed but we thought that we'd try at least the easy inside bolts on the port side. They took a little longer than expected but once out (we nearly stripped the head on one bolt), we went for the bolts on the outside port manifold. They took an hour to get out but finally the last of the 16 bolts were on the deck.

The next step is to remove the risers and unbolt the adapters that mate the to the manifolds. That probably won't be easy either, but at least we'll have real hex head bolts to work with. Or at least, we think we will. Who knows what lurks down there.

The cost of replacing the risers and the adapters appears to be about $350 per engine. Well worth it if it keeps seawater from getting into our engines.

Saturday, November 5, 2011

Pink stuff

After a great summer, during which Frances used the boat as her floating summer cottage when we weren't cruising, it's time to winterize.

Last weekend, we had a freak October snowstorm that dropped 8-10 inches of snow on Connecticut's trees that still had all or most of their leaves. The result was widespread power outages, some of which have now exceeded a week. Our street was almost impassible.

We got our power back in three days and one nice afternoon this week, we went to the boat and started that always sloppy process of winterizing the engines.

We have fresh water (actually antifreeze) cooled engines so we only have to run non-toxic antifreeze through the heat exchangers and the exhaust risers to protect us from freezing during the long winter to come. Funny to see snow on the boat on such a beautiful day in October.

Our boat came out of the water on Friday to make room for others who were coming up the Connecticut River for winter storage. Today (Saturday), we winterized the fresh water system, the air conditioner and the head and holding tank with another 10 gallons of pink stuff. Can't be happy until we see every faucet running pink.

Frances continued to put things away and get the interior ready for winter. One of her better discoveries was a way to vacuum bag much of our bedding. Put the bedding in a special plastic bag and then suck the air out using our vacuum cleaner. Worked like a charm. No air, no mold problems.

We have lots of things to do on the boat this winter, although we won't be spending every weekend doing them. But while we're not there, we left our little bear, who goes everywhere with us on the boat, standing guard.

Wednesday, October 26, 2011

Last cruise of the season

We left Norwich late in the morning on October 22 and headed back to Portland, our winter storage home. We stopped for fuel at Shennecossett Yacht Club in Groton and got a pump-out while we were there. Then we steered west, down Long Island Sound against a cool 15 mph wind. We had two good friends aboard, John and Joanne, who, as you can see, are experienced boaters.

Our starboard engine acted up as it has all season but with John aboard, we were able to narrow the problem down.

That didn't make much difference. Boating in New England with good friends during a nice day in October can be pretty nice. The Sound was cool and clear.

We left the Sound at Old Saybrook light and went into the Connecticut River. We've photographed these lights so many times but they still look good to us.

We passed many boats that were out on the river, the Becky Thatcher being one of them. Not very many colorful leaves this year.

And the Mary E. We have some history with this old boat. Nice to see her still working. And hello to Captain Ted, wherever you are.

We finally got to Portland as the sun was going down. No problem, as they were waiting for us. A little sad to turn off the ignition keys for the last time this year.

We'll continue our blog during the winter and into next summer and hopefully beyond. We have to two pictures of us, just enjoying being on our boat with friends. Frances says her hair looks crazy and I'm happy to even have any showing. We hope that you who read this blog had a great boating season.

Subscribe to:

Posts (Atom)