This blog is about our experiences enjoying and maintaining our 1980 Silverton 34C powerboat.

Sunday, December 28, 2014

Heads off but first, the water pump

We had a great Christmas and spent some time together cooking and laughing. Time well spent, as far as we're concerned.

This weekend we went back to the boat. We'll be lugging down all the new parts, each of which seems to weight at least 50 lbs. The new heads and the exhaust manifold are in boxes, which makes handling them a little easier. The intake manifold doesn't have box so getting it up on the boat will take some careful effort.

As we cleaned up the mating surfaces and got ready to mount the outboard head, we took a look at the raw water pump for that engine. We've never changed an impeller on it in the six seasons we have had the boat and it pumps seawater just fine. However, when we bought the boat it had two replacement pumps on board and, since the pump is (relatively) easy to get to with the upper end of the engine disassembled, we decided to install one of the new pumps. The old pump was a Sherwood and the new one a Jabsco, but they appeared identical.

Its worth noting that these pumps are expensive - $380 each - and it isn't possible to simply change the impeller as you would with most seawater pumps. You can buy a rebuild kit but to use it, you must remove the pump and the pulley, which is pressed onto the shaft. All the more reason to replace it now, which we did. If we have time, we'll do the port engine as well.

Of course, we got to learn all about how Chrysler went about mounting the pump. It has a bracket that bolts to the circulating pump with two 9/16" brass bolts. The pump mounts on the top bolt and the bottom one slides along a slotted arm so that the drive belt can be adjusted. Sounds good but it wasn't easy. We laid across the top of the engine (mating position, kinda) and reached down under the front to extract and then reinstall those two bolts.

We got it mounted okay but couldn't push the inlet hose back on. Then we removed the new pump completely, coated the inside of the inlet hose with dish washing liquid and forced it in place. Eventually, that worked. Elapsed time about two hours. Doesn't look like we're going to do this for a living.

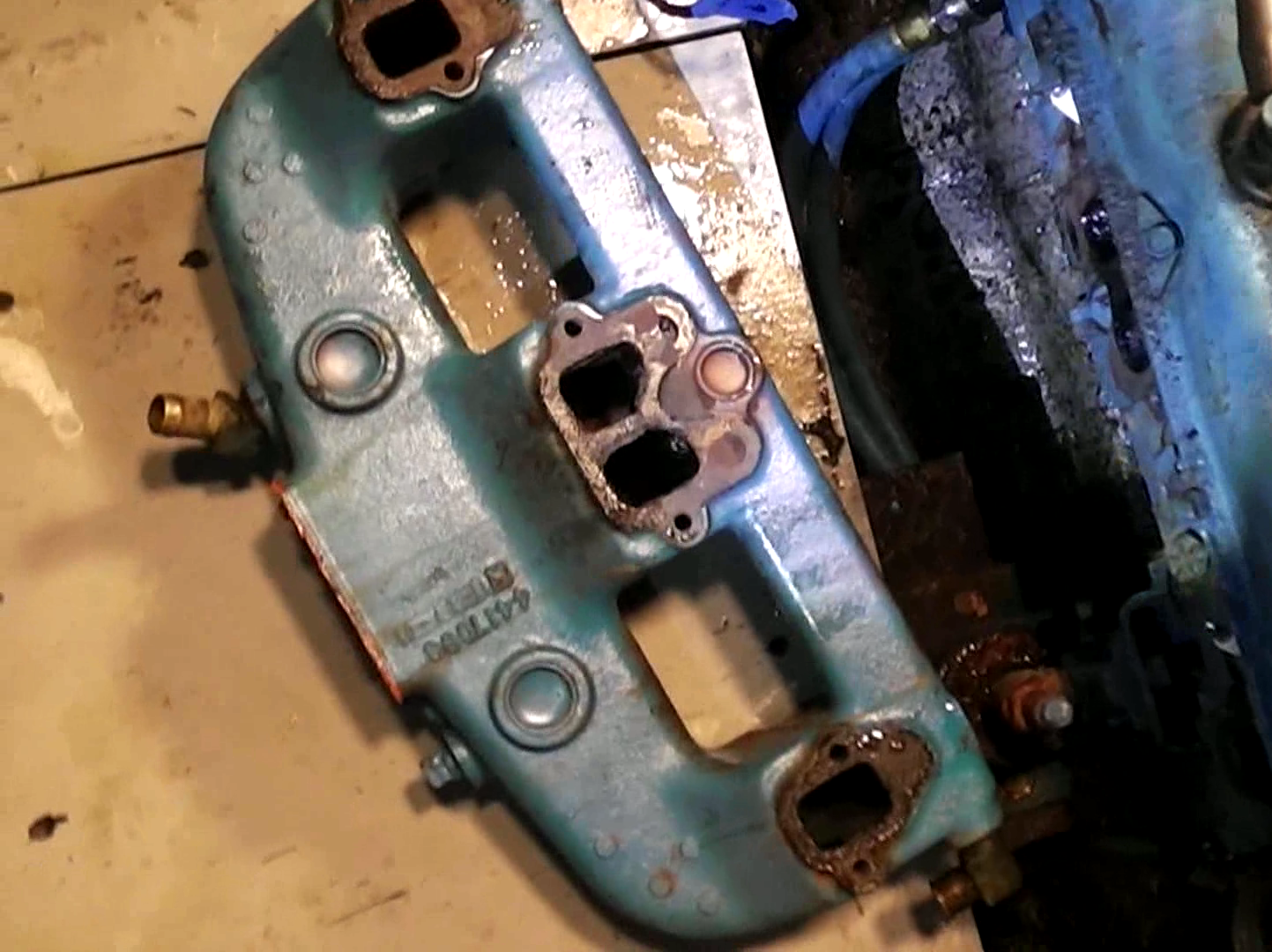

Before we left on Sunday afternoon, we spent some time cleaning up the mating surfaces on the inboard exhaust manifold that we've decided to keep. It really doesn't look bad at all and since we're basically cheap New Englanders, we'd really like to re-use it. But, now we wonder.

We're going to give this some thought. It's one of the last things we have to replace so we have some time. $350 for a new one is a half a tank of marine gas. Doesn't sound so bad when you think of it that way.

We've added some video. We've started narrating and while Bill looks like an old vagrant, it does add a dimension that old videos didn't have. Now all we need to get him better lighting, cleaner clothes and more hair.

Sunday, December 21, 2014

Heads off

The thermometer in the cabin must have been off because it felt a lot colder than 34 degrees when we arrived at the boat on Saturday. But, we were there, determined to get the cylinder heads off the engine this weekend. Our little electric heater cranked the temp up to a nearly tropical 40 degrees in no time and we were ready with a large hammer and pry bar to get those heads loose.

It really only took a couple of taps and the inboard side head came free. We had been worried about lifting it but it was really quite easy. We had drained that side of the engine but we still got some antifreeze in the cylinder bores, all of which we got out.

The inboard head really didn't look that bad but the problems are with cylinders 5 and 7 and those are on the other side.

Love those Puppy Pads for soaking up the grease.

Then we tackled the outboard head, (the one closest to the hull) the one more difficult to reach. It came off, too, and we set it up in the cockpit. (We have better muscles than we thought we had.)

The photo isn't very clear but you can see the rusty #5 intake valve.

The video will show it more clearly, but this is the cylinder with just 95 lbs pressure. The combustion chamber is also full of crud. The head gasket doesn't look bad but the exhaust manifold on that side might be where the water was getting in. That manifold doesn't look all that good and as part of this project, we're going to replace it.

We've lined up all the old parts so they can be taken off. We're going to wrap them in old towels to make them a little easier to handle but getting them from the swim platform down to the ground should be cute.

We've also been busy after work during the week cleaning up the intake manifold and the two valve cover gaskets, all of which were rusty and coated with crud. We stripped, primed and painted the valve covers and they look like new.

The mounting bolts and washers got the same treatment after we mounted them on a piece of scrap plywood to protect the threads.

The intake manifold was a lot of work. First, we sprayed it with degreaser and flushed that off with a hose. Then we hand-scraped the remaining rust and crud off, and finished it off with a wire wheel. After masking, we used Rustoleum Rusty Metal Primer before the final Rustoleum Sail Blue.

Frances says that I'm a nerd for doing all this extra cosmetic work but I'd rather put clean engine parts back on than take the lazy way out.

We're down to mounting the new heads. We took everyone's advice and will replace not only the head bolts (that must be replaced, as we understand it) but all the mounting bolts and washers on the exhaust and intake manifolds.

That effort started us hunting for bolt sets for the Chrysler 360 engine. The usual suspects such as Summit Racing had them but at a price that we thought was way out of line. Then we remembered our last engine rebuild project more than 10 years ago when we went to Bolt Depot www.boltdepot.com in Weymouth, Mass. for what we needed. Bolt Depot is a real, family operated retail store and they had every Grade 8 bolt we needed on their beautiful website for less than $30. They are going into our boat maintenance folder as a great source.

Monday, December 15, 2014

Waiting for winter

The weather has been excellent and when we left the boatyard on Sunday, it was warm and clear. Before we left, we took some still photos of some of the boats, most of which were covered in shrink-wrap,

We know many of these boats, having been here, at least in the winter, for almost 30 years. And we knew their owners and their propensity for Budweiser.

But, time passes and we still have our boat here for the winter.

Sometimes, when we leave, we take pictures of the boats in storage. Most will live again next spring. Some are owned by a bank that probably shouldn't have made the loan in the first place and some others will never see the water again. Those are the boats that are seeing the last years of their life. We think about how much fun people must have had on them; how many kids learned to steer at that now discolored helm; how many people caught and bragged about their big fish from that deck.

These old boats have memories and as hard as we listen, they never give up their history. One can only imagine...\

We know many of these boats, having been here, at least in the winter, for almost 30 years. And we knew their owners and their propensity for Budweiser.

But, time passes and we still have our boat here for the winter.

Sometimes, when we leave, we take pictures of the boats in storage. Most will live again next spring. Some are owned by a bank that probably shouldn't have made the loan in the first place and some others will never see the water again. Those are the boats that are seeing the last years of their life. We think about how much fun people must have had on them; how many kids learned to steer at that now discolored helm; how many people caught and bragged about their big fish from that deck.

These old boats have memories and as hard as we listen, they never give up their history. One can only imagine...\

Sunday, December 14, 2014

Removing the head bolts the hard way

How would you like to find these 10 bad boys in your bed? Three lengths, depending on where they go. It took us about an hour to get all 10 out, We used a 6-point, 3/4" socket on a 16-inch breaker bar and we have to say that they were difficult to bust loose. Our bet is that they've been in there since this boat was built.

We began by taking off the rocker arm assembly from the hull-side of the engine and stashing those parts away with everything kept in the same order. The pushrods - actually all of the valve train parts - looked fine and quite clean.

We also removed the alternator and a couple of other cooling hoses that will get in the way once we pull those old heads off.

When we got down to those inboard head bolts, our morning friskiest faded fast. Those bolts are hard to get off. Next step is to get a longer breaker bar or, failing that, a quick change of underwear. We really don't want to walk funny for the next week.

We're also going to have an issue with getting the old heads off and the new heads onto the boat. The heads weigh about 35 lbs. each and we're going to have to get some help picking the old ones up to the cockpit, then up to the deck and then down a ladder to the ground or to the swim platform, where they can be taken off.

Sunday: A bigger breaker bar does it

It's amazing what happens when you use the right tool. We bought a 25-inch, 1/2-inch drive breaker bar at Harbor freight on our way to the boat. $12.95 well spent. The remaining head bolts gave up without any issue. Size does matter, it seems.

We also disconnected lots of little things that were bolted to the heads such as the dipstick tube, the lifting rings and the box that contains the engine circuit breaker. Once the heads were completely disconnected, they didn't exactly jump of the block. We pried and tapped but no, they aren't going to come off without a fight. We'll put some muscle behind it next weekend and see if we can get them off.

Yes, this is taking a while

We know that some of our dock mates could change these cylinder heads in a weekend or less but unfortunately, we can't. We captain a desk all week, thinking of amazingly effective promotions for our clients. On Saturday morning, we put on our old clothes and headed to the boat. We haven't swapped heads in more than 15 years so we've gotten a little stale (and older). Don't worry. We'll get this done.

In the meantime, we post these blogs and their associated videos, which we enjoy planning and editing. No Academy Awards, but it still helps us keep up with how video is done these days, and of course, for those of you who know us, it's a way to keep in contact over the winter.

Wednesday, December 10, 2014

A really good vendor experience

We just ordered about $500 worth of manifolds and gaskets for our cylinder head replacement project. Obviously, we shopped around for price and availability and settled on Lighthouse Marine in Riverhead, New York http://www.marineengineparts.com/

We did that for several reasons. First, this is a real, second generation business with a warehouse full of marine parts. We've been there and liked the way we were treated. Second, the guys behind the counter know what they are talking about and those same guys are the ones you get when you order parts by phone. Finally, what's not to like about an Internet marine supplier that also owns a very nice marina? It's right down the street from their store.

We ordered today using the Internet because we had all of the part numbers ready. Since Lighthouse is on Long Island, we'll get the parts tomorrow and the shipping cost was $20, pretty reasonable given that the manifold we ordered weighs about 35 lbs. alone.

I received an acknowledgement from Greg, the company's business manager, within 5 minutes. A few minutes later, Greg called me. He was concerned about the head gaskets that I had ordered. Was I sure that I wanted these Chrysler NOS head gaskets? I said that I thought I did, given the description.

We discussed the possible differences in what he had and what I needed. Since by then, I was at his website, he gave me another part number, a Fel-Pro head gasket set and I looked at it. I pointed out that the application for that Fel-Pro gasket set was for 7.4 liter Ford engine and not for my engine, a Chrysler LM-360.

There was a short silence after which he said, "Our description is wrong. This Fel-Pro gasket set is for a Chrysler LM-360." He went on to say that the Fel-Pro gaskets were the "gold standard" in gaskets and they had never had any problems with their customers using them.

The Fel-Pro gaskets cost a little more so we revised the order to cover that.

Our point here is that this is the way buying marine parts on the Internet should work, but rarely does. It would have been easier for Lighthouse to send us the wrong gaskets and then play around with us getting an RMA to send them back.

But they didn't. They examined our order, found a problem and called us to resolve it. That's what happens when your supplier knows boats and values the relationship.

We did that for several reasons. First, this is a real, second generation business with a warehouse full of marine parts. We've been there and liked the way we were treated. Second, the guys behind the counter know what they are talking about and those same guys are the ones you get when you order parts by phone. Finally, what's not to like about an Internet marine supplier that also owns a very nice marina? It's right down the street from their store.

We ordered today using the Internet because we had all of the part numbers ready. Since Lighthouse is on Long Island, we'll get the parts tomorrow and the shipping cost was $20, pretty reasonable given that the manifold we ordered weighs about 35 lbs. alone.

I received an acknowledgement from Greg, the company's business manager, within 5 minutes. A few minutes later, Greg called me. He was concerned about the head gaskets that I had ordered. Was I sure that I wanted these Chrysler NOS head gaskets? I said that I thought I did, given the description.

We discussed the possible differences in what he had and what I needed. Since by then, I was at his website, he gave me another part number, a Fel-Pro head gasket set and I looked at it. I pointed out that the application for that Fel-Pro gasket set was for 7.4 liter Ford engine and not for my engine, a Chrysler LM-360.

There was a short silence after which he said, "Our description is wrong. This Fel-Pro gasket set is for a Chrysler LM-360." He went on to say that the Fel-Pro gaskets were the "gold standard" in gaskets and they had never had any problems with their customers using them.

The Fel-Pro gaskets cost a little more so we revised the order to cover that.

Our point here is that this is the way buying marine parts on the Internet should work, but rarely does. It would have been easier for Lighthouse to send us the wrong gaskets and then play around with us getting an RMA to send them back.

But they didn't. They examined our order, found a problem and called us to resolve it. That's what happens when your supplier knows boats and values the relationship.

Monday, December 8, 2014

Installing new cylinder heads - Progress on a cold weekend

We're glad that we don't do this for a living because if we did, we'd starve. We know that people do jobs like this every day but we have to re-learn a lot, given that we haven't changed marine cylinder heads in about 10 years and even then, they were familiar GM V-8 engines. This time, it's a Chrysler 360 V-8 and there are some differences.

When we left last week, we had the outboard starboard exhaust manifold up against the water tank and hanging from two studs.

We decided to think about how to remove it and during the week came up with a nautical solution that worked perfectly. It involved putting a dock line through the manifold and then suspending it from a crossbar. That took the pressure off the those two remaining studs. The result was that we got that outboard manifold off. Then we could move this project along a little.

It took another hour to remove the two valve covers. These things might have been on there for 30 or more years and it took some patience to finally get them off. They looked good inside, however. No sludge, so we'll clean them up and reinstall them when we finally get the new heads installed.

The intake manifold bolts (all 12 of them) came out but if we hadn't had the offset box wrenches that we bought at Harbor Freight, we 'd still be down there trying to do it with straight box wrenches. The angle of the bolts was really hard to reach and using sockets was out of the question.

With the bolts out, we tried to get the manifold off but it wouldn't budge. By then, we were cold and tired and we've learned in the past that it's sometimes better to quit and try again another day.

It's amazing what a good night's sleep will do because when we arrived on Sunday, we used a small crowbar to tap around the edges of the manifold. It began to move a little and we were able to lift it right off the engine.

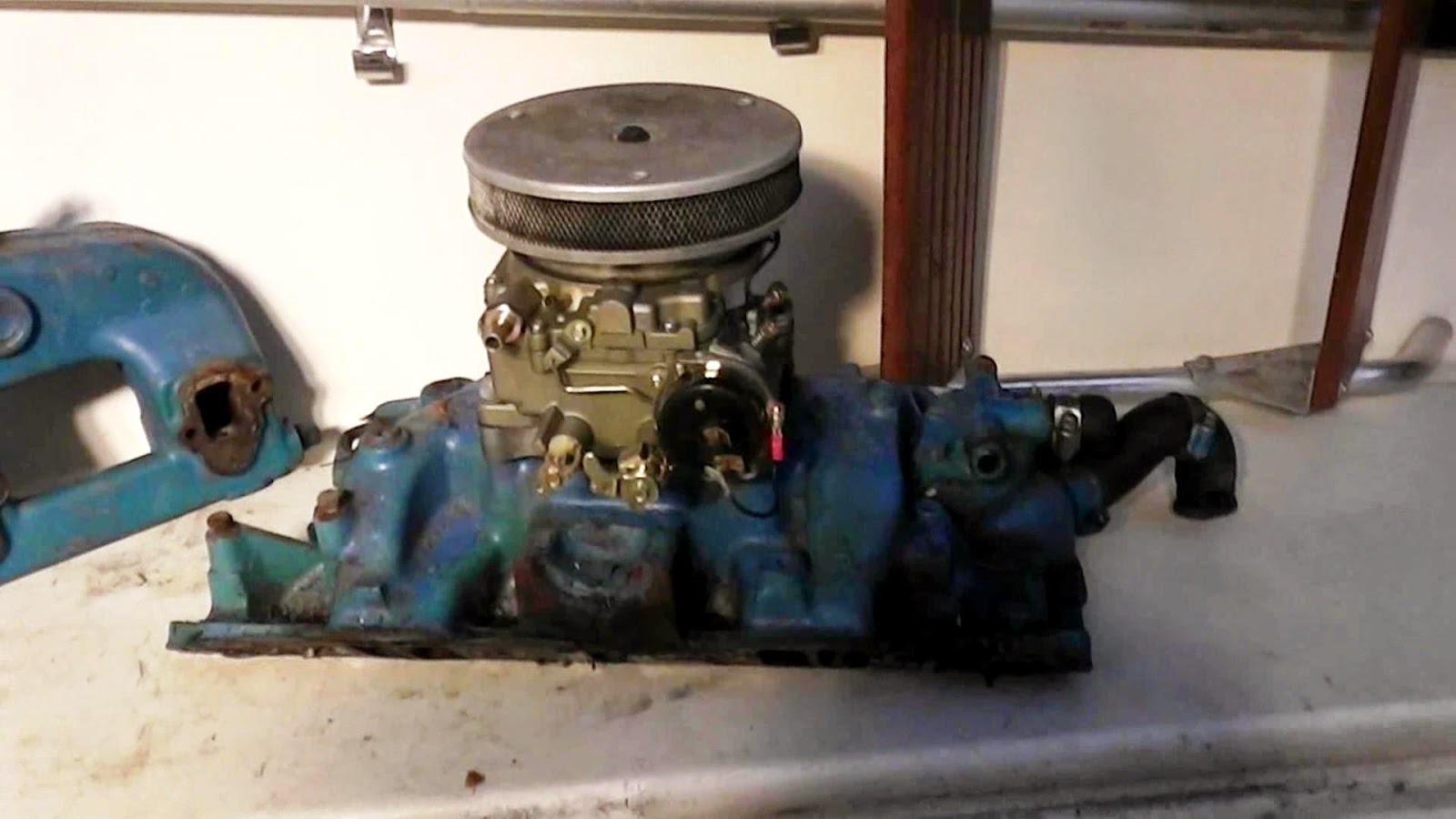

We took the carb off (should have done that first) and put the manifold in the car so we could take it home and scrape the old gasket material off and clean it up a little.

Since we were on a roll, next we removed the rocker arm assembly and the pushrods from the inboard side of the engine. We laid all of those parts out by the numbers because they are supposed to go back into their original positions.

After we get the inboard head off, our plan was to begin on the other head but now think that's not the best way to do it. It appears that a better way is to replace the head on in inboard side and reinstall the rocker arms, pushrods and valve cover as well. That will keep debris out of that side of the engine and give us some practice before we begin the outboard head. That outboard side is up against the water tank and will be much more difficult to do. We'll approach that one knowing exactly what wrench to use and that will be helpful since getting that head off is going to require doing things at least partially by touch and feel.

Here's some of what it looked like this weekend.

When we left last week, we had the outboard starboard exhaust manifold up against the water tank and hanging from two studs.

We decided to think about how to remove it and during the week came up with a nautical solution that worked perfectly. It involved putting a dock line through the manifold and then suspending it from a crossbar. That took the pressure off the those two remaining studs. The result was that we got that outboard manifold off. Then we could move this project along a little.

It took another hour to remove the two valve covers. These things might have been on there for 30 or more years and it took some patience to finally get them off. They looked good inside, however. No sludge, so we'll clean them up and reinstall them when we finally get the new heads installed.

The intake manifold bolts (all 12 of them) came out but if we hadn't had the offset box wrenches that we bought at Harbor Freight, we 'd still be down there trying to do it with straight box wrenches. The angle of the bolts was really hard to reach and using sockets was out of the question.

With the bolts out, we tried to get the manifold off but it wouldn't budge. By then, we were cold and tired and we've learned in the past that it's sometimes better to quit and try again another day.

It's amazing what a good night's sleep will do because when we arrived on Sunday, we used a small crowbar to tap around the edges of the manifold. It began to move a little and we were able to lift it right off the engine.

We took the carb off (should have done that first) and put the manifold in the car so we could take it home and scrape the old gasket material off and clean it up a little.

Since we were on a roll, next we removed the rocker arm assembly and the pushrods from the inboard side of the engine. We laid all of those parts out by the numbers because they are supposed to go back into their original positions.

After we get the inboard head off, our plan was to begin on the other head but now think that's not the best way to do it. It appears that a better way is to replace the head on in inboard side and reinstall the rocker arms, pushrods and valve cover as well. That will keep debris out of that side of the engine and give us some practice before we begin the outboard head. That outboard side is up against the water tank and will be much more difficult to do. We'll approach that one knowing exactly what wrench to use and that will be helpful since getting that head off is going to require doing things at least partially by touch and feel.

Here's some of what it looked like this weekend.

Monday, December 1, 2014

Installing new cylinder heads - Exhaust manifold removal first

After enjoying a great Thanksgiving and working the next day, on Saturday we were ready to tackle the removal of the inboard starboard exhaust manifold. Last weekend, we started on this but managed to round over one of the six bolts that hold the manifold to the cylinder head and we didn't have the required Allen key to remove the adapter from the top of the manifold. Hey, it was the first day of a new project and it took us a while to get everything on the boat we needed.

Saturday, we were better prepared. During the week, we visited Harbor Freight and bought an inexpensive set of 3/8-drive, six-point sockets. We own hundreds of sockets but not many of the six point deep well variety.

Once on the boat with all of the lights hooked up, we tried the manifold bolt with the rounded head and the six-point socket backed it out immediately. We had to disconnect a couple of water lines and the manifold was ready to come loose.

Chrysler marine exhaust manifolds have three mounting points (unlike GM small block V-8 manifolds that have four). Chrysler also uses studs on the forward and aft-most manifold mounting points and three-inch long bolts on the four others. That makes sense because you can remove the bolts and then the nuts on the two studs and then pull the manifold off, sliding it on the studs.

One tug and the manifold came loose and we slid it out and off. From its outward appearance, the manifold didn't look bad. In fact it looked very good. We shined a light down into the ports and there was absolutely no rust. In fact, except for some carbon, it looked almost new.

We have no idea when these manifolds were last changed but from the look of two mismatched washers on the mounting bolts, these manifolds weren't original. Our engines are cooled in such a way that only a 50-50 percent mixture of antifreeze and water ever passes through the manifolds. Seawater is used to cool the heat exchangers and the exhaust elbows. That means that they should last a long time.

If the other manifold looks this good (and we bet it will), we'll save about $630 by reusing them.

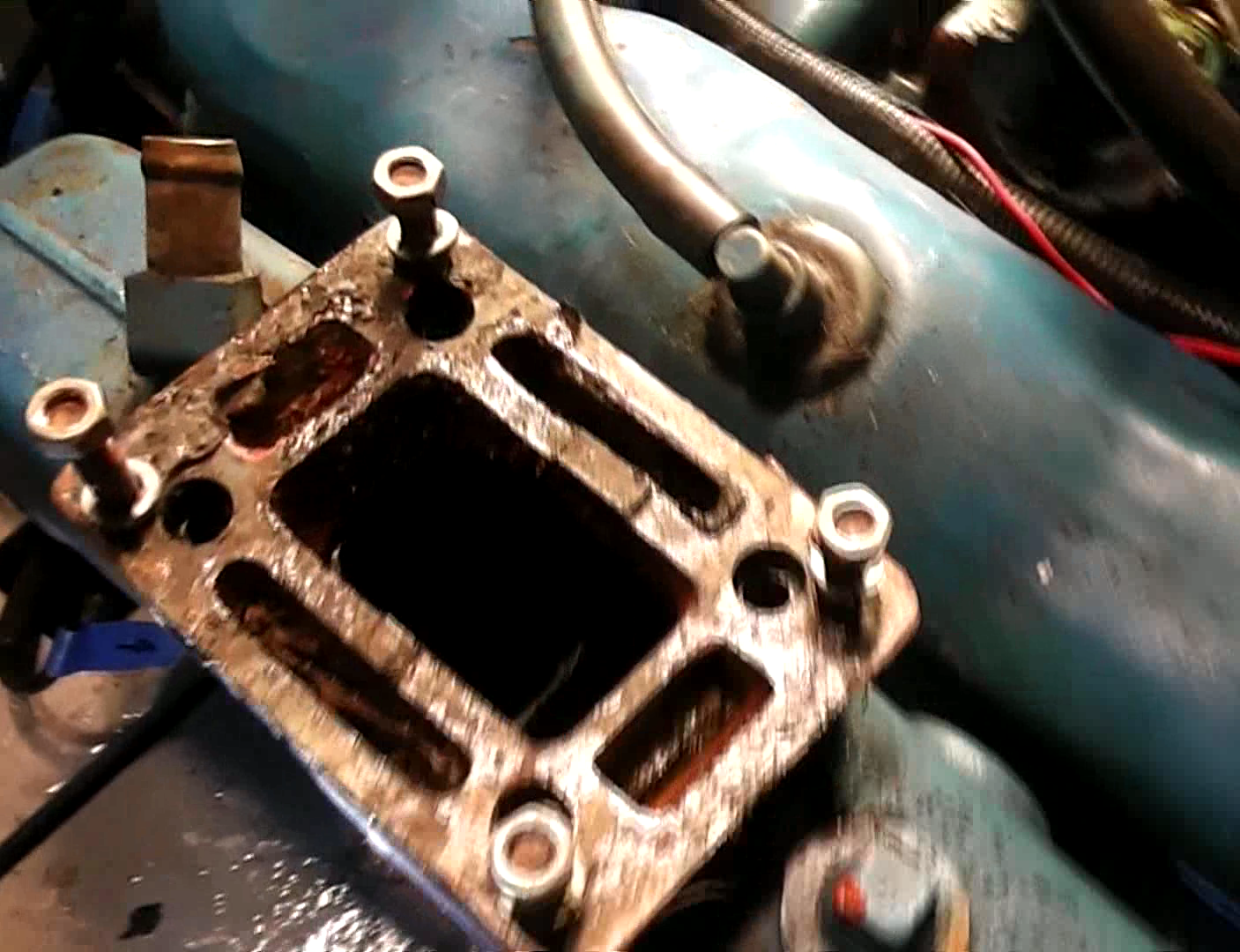

The match between the manifold and the exhaust elbow is made through an adapter. It uses a block-off gasket to keep seawater out of the manifold.

We've brought this adapter home and will clean it thoroughly and re-use it.

Ugh! on Sunday

On Sunday, it was 45 degrees, plenty warm enough to get that other riser and manifold off. Having done the inboard manifold and riser on the inboard side just yesterday, the outboard manifold went pretty quickly until we ran into a major snag.

After disconnecting the water hoses, we easily removed the riser. With that gone, we tested the studs on the ends of the exhaust manifold to make sure that the studs didn't unscrew when we removed the nuts. They didn't, so we took out the other four manifold bolts. Getting a wrench in there so close to the water tank took a little stretching but they did come out. You can see how close the water tank is in this picture.

Next, we slid the manifold out away from the cylinder head but before it was free, it came in contact with the fiberglass fresh water tank. We tried moving the tank, but it's up against the hull so it isn't going anywhere.

We didn't notice this until we looked at these pictures while writing this blog post, but that manifold appears to be cracked. We can't wait to look at this in more detail when be get the damn thing out but whatever we find, that manifold is going to the Dumpster.

Here's what it looked like when we left on Sunday afternoon... one manifold hanging from two 3/8" studs. Looks like we'll have to cut them off.

We would liked to have been able to get that manifold off so we can begin removing the intake manifold but looks like we'll have to stop and deal with this first. But, it's a boat, so nothing goes exactly as planned.

Monday, November 24, 2014

Replacing the cylinder heads - Beginning

Thus fortified, we made our way to the boat. The idea was to give Frances a chance to take some last items off the boat for the winter.

While she did that, I took a look at what I'd have to do to replace the heads on our starboard engine.

Several years ago, we replaced the all four risers and had the heat exchangers rebuilt, so this wasn't new territory for us. We didn't really have all of the tools required but while Frances was busy, we took a look at removing the inside starboard manifold, since that was the easiest one to access.

As you'll see in the video, the riser on that side came off without much effort. The bolts on the manifold also came out, except for one, where we rounded the head of the bolt. We can get that out but we didn't have the tools necessary right then. The other bolts holding the manifold in were in quite good condition so we have to think that the manifolds had been replaced before with good quality hardware. That's good because we don't want to break off a bolt.

Next weekend, we'll take everything off that side and all the other stuff we're going to have to remove. At least that's what we'll try to do.

Sunday, November 16, 2014

The last of the pink stuff

Saturday morning saw us back on the boat with a few more gallons of pink antifreeze. Nothing like seeing this stuff disappearing into our fresh water tank only to be pumped out in the spring.

But it's better than freezing and damaging all that new plumbing we installed last winter. We think we under estimated the capacity of our water system's new hot water heater. We drained it and then refilled it with antifreeze. With our new pump (see our last blog post concerning what we think of that thing), we got lots of antifreeze in the sink in the head as soon as we turned the pump on.

Then, the final test. Unless we have a serious urinary condition, this is a winterized toilet.

Thank God that's over!

On Sunday, we had planned to begin work on our starboard engine but the leaves, of which we have many, caught our attention and we raked the yard and cleaned out the gutters. Not as good as wrenching on our boat, but something that just has to be done.

Meanwhile, Frances was busy making an apple pie and she certainly can bake! Some time this winter, we hope to create a video on how she does it. Rehearsals are already under way and she is looking forward to it.

Wednesday, November 12, 2014

This kind of workmanship drives people away from boating

We just finished installing a new fresh water pump. Why do that at the beginning of winter? Well, when we went to pump potable antifreeze from our on-board water tank through the lines to the galley and head, our five year old ShurFlow Extreme Series pump wouldn't pump. No suction at all although the motor ran fine.

We know what you're thinking: It lasted five years. Sorry, but it didn't. Two years after we installed it, the diaphragm failed and we took it apart and replaced the old diaphragm assembly. That pump cost over $200 new and the rebuild parts were well over $100.

And, we're not running a charter boat here with a bunch of guys flushing their way through 45 gallons of fresh water, five or six days a week. During the summer, we're at a marina, drinking and washing in city water. We only use that pump when we are underway and that's not what we'd call extreme usage at all.

Cold weather is predicted here which means we should pump the pink stuff through our water lines sooner rather than later. We ordered a new pump from Defender Marine and because we don't have time to re-plumb the system to accept a completely different pump, we ordered a ShurFlow Par-Max Plus pump, which is very close in appearance and performance to the extremely failed old pump.

How long will the ShurFlow Par-Max Plus pump last? Judging from the price, probably not as long as good old Extreme. Par Max Plus cost $132 (plus $11.15 shipping and $9.15 tax) and that's a lot less than the old Extreme pump was.

Here's the old pump. Not only doesn't it pump, but it's rusty even after being in an area that is relatively dry. We're not sure that any of the pumps from competing manufacturers are any better, but if you are in the market for a pressure water pump, avoid ShurFlow or look forward to an hour in the engine space to replace it fairly regularly.

We know what you're thinking: It lasted five years. Sorry, but it didn't. Two years after we installed it, the diaphragm failed and we took it apart and replaced the old diaphragm assembly. That pump cost over $200 new and the rebuild parts were well over $100.

And, we're not running a charter boat here with a bunch of guys flushing their way through 45 gallons of fresh water, five or six days a week. During the summer, we're at a marina, drinking and washing in city water. We only use that pump when we are underway and that's not what we'd call extreme usage at all.

Cold weather is predicted here which means we should pump the pink stuff through our water lines sooner rather than later. We ordered a new pump from Defender Marine and because we don't have time to re-plumb the system to accept a completely different pump, we ordered a ShurFlow Par-Max Plus pump, which is very close in appearance and performance to the extremely failed old pump.

How long will the ShurFlow Par-Max Plus pump last? Judging from the price, probably not as long as good old Extreme. Par Max Plus cost $132 (plus $11.15 shipping and $9.15 tax) and that's a lot less than the old Extreme pump was.

Here's the old pump. Not only doesn't it pump, but it's rusty even after being in an area that is relatively dry. We're not sure that any of the pumps from competing manufacturers are any better, but if you are in the market for a pressure water pump, avoid ShurFlow or look forward to an hour in the engine space to replace it fairly regularly.

What happened to reliable equipment?

Here's another example of poor workmanship that we, unfortunately, own. It's our Standard Horizon Chart plotter.

This picture was taken when it was new, five years ago. Since then, the plastic cover has deformed, yellowed and no longer fits. But better yet, the unit itself is no longer reliable. When we set it to record miles traveled on a cruise, the result shown is roughly double the distance we have actually covered. On a recent cruise, our location was shown to be in the middle of a Connecticut state park when we were actually in the channel on the Connecticut River. Gee, just a mile or two off.

The Standard Horizon Chart plotter also came with an instruction manual that is beyond bad. Whoever wrote it has never been on a boat trying to figure out what button to push to simply display a route. That should be easy. The small computer we use to really navigate does that in a split second and it displays exactly where we are and how much distance we have traveled. It cost lot less than the Standard Horizon unit and it's now four years old.

We won't belabor this but looking at the chart plotter photo reminds us that the people who designed our Icom M-412 VHF marine radio also have never spent any time on a boat. The mic cord for this radio maxes out at maybe 35 inches. That means that we can't stand up while operating the radio. In fact, you have to bend over to use the mic while seated at the helm. Guess we should relocate our helm chair, right?

Sorry to spend your time on this rant. There are many other things we could complain about in the recreational boating world but this is probably enough for now.

Saturday, November 8, 2014

Winterizing our engines

We winterized on Tuesday, November 4 during a very nice afternoon. Obviously, we only do this once a year and despite the fact that we've been doing it to our various boats' engines for perhaps 35 years, it is always a little sloppier than we remembered. Lots of hot oil, full oil filters and many jugs of oil and antifreeze to be poured or pumped. We wear plastic gloves but never attempt this task wearing any clothes that would be acceptable outside of a boat yard. The old hoodie that Bill wore on Tuesday has the stains of many colors of bottom paint going back 12-15 years.

Changing the oil

The sloppiest part of this job is always changing the oil filters and that's where we begin. First, we start the engines and warm them to thin out the engine oil and make it easier to pump out of the crankcases. Then we remove the oil engine oil filters. Some time ago, we moved the filters from the engines themselves (where they were almost impossible to reach) to remote mounts in front of the engines. (Our engines are on v-drives, so the engines face aft.)

Putting the new filter on is pretty straightforward but it has to be filled with fresh engine oil first. A filter like this Fram PH8A takes about a quart. The whole oil change is supposed to total five quarts on our engines but another one-half quart is needed to also fill the remote oil filter lines, which are about three feet long each. Note the old filter in its baggie. Zip-lock bags are great for containing that crappy old oil.

Next we suck out the old oil from the crankcases.

We use a Marpac Fluid Xtractor. I think we've owned at least three or four oil pumps, both electric and vacuum, over the years but this one, now five years old, is the only one that really works. Give the handle a dozen or so pumps and it starts pulling the old oil up through the dipstick tube almost immediately. It holds 4.2 quarts and it does need to be pumped again a couple of times to get the last of the old oil out.

Once both engines have been filled with fresh oil, we start them up, watch the oil pressure build and check for leaks.

Winterizing the cooling system

Over the years, we've assembled some tools for this task. One is an old six gallon bucket that once held some industrial flavoring. We cut a hole in the bottom and added a valve and then a long section of hose. This thing has winterized our boats for many years. Yes, it leaks a little, but for the few minutes it's in use, who cares? It all goes into the bilge.Then we go to the thru-hull fitting that feeds seawater to the boat's heat exchangers. Here, we've added a simple t-fitting that will allow the engine to draw antifreeze from our bucket, after we have closed the sea cock.

Fill the bucket with three gallons of antifreeze, open the valve and start the engine and about 45 seconds later, pink antifreeze is flowing out the exhaust and the bucket is empty.

It's probably worth mentioning that our engines are "fresh water" cooled, meaning that the cooling of the engine block itself and part of the exhaust manifolds is done through a heat exchanger that is actually filled with a 50-50% mixture of ethylene glycol (green) antifreeze and water. The pink antifreeze that we're using here only protects the seawater circuits in the heat exchanger and exhaust manifolds. That's why we can do it with just three gallons of pink antifreeze.

We've seen lots of discussion of this pink stuff on Internet forums. We shop for the best price and this year paid $3 a gallon at Tractor Supply. We've used this antifreeze through a number of very cold winters here (-20 degrees F at times) and have never had a freezing issue.

We ran out of time before we could winterize the boat's hot and cold water systems but we'll do that next weekend.

We've added a video showing some of this process. At this point, it clearly shows that Bill needed a haircut. Other than that, it was fun to do and to play narrator.

Wednesday, November 5, 2014

Frances comes up with stacked eggplant

Sunday, November 2, was much too cold and windy to winterize our boat engines. Maybe we're getting old, but why freeze your butt off when better weather is coming soon?

Too tell the truth, we both needed a day off and we spent Sunday reading the New York Times, puttering around the house and generally being relaxed.

Frances had gathered some ingredients that she felt would make a good dinner and, as it turned out, it was very tasty. Once she got started, we decided to shoot some video. It's a little silly but we thought worth preserving. It's not about boating, but who cares? We love to look back on these little videos and laugh. We hope you will too.

Saturday, November 1, 2014

Getting ready to winterize the boat

It's Saturday, November 1 and the boat has been sitting in Portland for a week. We had too much to do this week to begin winterizing it but today, despite rain and quite a lot of wind, we hauled down all the antifreeze, engine oil and filters down to the boat.

We got pretty wet and cold bringing the stuff down from the car. Guess we forgot how heavy three of four gallons of antifreeze is but we got everything stowed on the deck. The cost of the oil, filters and both pink and green anti-freeze was $100 from Tractor Supply.

We normally don't need the Ethylene Glycol (green) antifreeze since it's used in a 50-50 percent mixture with water in our engine heat exchangers, but in a few weeks, we're going to replace the heads on our starboard engine and in that process, we'll probably lose some. Yes, we normally check the solution in the heat exchangers with a hydrometer. Better to be safe....

If the weather improves, we'll get the engines, air conditioning pump and the hot and cold water systems done tomorrow.

We also like to change the engine oil and filters before we store the boat. No sense in leaving the old contaminated oil in the engines for the next five months. Five months? That doesn't sound good at all!

Before we left, we stripped the v-berth beds and stuffed everything into a giant garbage bag. Frances has volunteered to get all this stuff washed and then vacuum bagged to the winter. Boy, do we love vacuum bagging! Hook it up to a vacuum cleaner, throw in a dryer sheet and all that bedding is reduced to two small cubes.

We put a camera mount on one of our aft rails and shot some video of us carrying down the stuff from the car. Not exactly thrilling video but we'll look at it and laugh next spring.

Tuesday, October 28, 2014

Taking our stuff off of the dock

With the boat safely tied up in Portland, we had to do what we call the "car switch," familiar to many boaters, we're sure. Once you take your boat out of its slip for the year, you have to leave a car there and on Monday, we took some time to retrieve our other car and, while we were there, remove our fenders and boat stairs so that they could be safely stored at home. Bill drove Frances' car to the marina and drove his old station wagon back home with Frances following. This was her first long solo drive since her eye surgery and she did just fine.

Once we got to the marina, we set up our cam and began hauling slime-covered fenders and our boat stairs up to our station wagon. We speeded up the video and cut out the boring parts so viewers wouldn't fall asleep.

Once everything was loaded we took ourselves out to lunch at "5 Guys," which, for a burger place, isn't really that bad. The fries were about 10,000 degrees when served but since most of them are in the bottom of a paper bag, they cool quickly.

We enjoyed talking about our summer and all the friends that we have on A-dock. But, as the saying goes, "All good things must come to an end," Not really an end. We'll be back next summer!

Sunday, October 26, 2014

Seas 1 Ft. or Less

It was Saturday, October 25 and we'd been watching the weather all week. Each day there was more rain and wind with a Gale Warning in Long Island Sound on Wednesday and Small Craft Advisories just about every other day except Saturday.

The Saturday forecast held and that would be our day to make the 60 mile run from Norwich, our summer dock, to winter storage in Portland. When we got up early Saturday morning the exact forecast was:

"TODAY W WINDS 5 to 10 KT WITH GUSTS UP TO 20 KT. SEAS 1 FT OR LESS... THEN 1 TO 2 FT THIS AFTERNOON."

We're not weather pussies when it comes to boating but we'd rather not run through seas that rearrange the furniture in our cabin if we don't absolutely have to.

Our friend and dock mate, John T., volunteered to go along and that was really nice since Frances didn't really feel up to straining her eye just as it was slowly healing.

At 8:15 AM, we untied the lines and steered out into the Thames River. It was cold but the river was like glass, as you can see in the photo above. The 13 mile trip to New London was uneventful. The fall colors were somewhat muted but who cares? We were on our boat and that always makes it a beautiful day.

At New London Ledge Light we turned west into the expected wind but there was almost none. The Sound was flat and we laughed at the accuracy of the "1 ft. or less" prediction. Our course took us 3.8 miles to Bartlett Reef and as we approached, we noticed many whitecaps ahead of us. Whitecaps? To us that means wind at 20 Kts. or better. That turned out to be fairly accurate as we turned about 30 degrees further west toward Old Saybrook. The wind came up and so did the seas, which were wind driven waves of the 4-5 ft. variety, right on our nose.

But, we we often say, "That's boating," as we slogged through the next 9.3 miles. We had to be very careful going down the ladder from the bridge just to use the head. The wave frequency was just right for the maximum bang-and-slam effect. Sorry, no video. We were a little too busy to turn the camera on.

Of course, the boat did just fine and we got into the breakwater at Old Saybrook with nothing more out of place than a set of kitchen knives that landed in the sink and a bottle of something in the head that left the vanity and ended upside down in the toilet.

The 33 mile run up the Connecticut River was also without drama. It was great to have an experienced boater like John along and I think we discussed - and solved - most of the world's problems that afternoon.

At Haddam, we encountered several boats waiting for the East Haddam Swing Bridge to open. We've been under that bridge 100 times and we've never had to have it open, even during the spring freshets but the Bertram in this photo appeared to be a little too tall.

We went for it (as you'll see in the video) and as we got close, John was able to read the depth gauge as 20 ft. That's probably 3-4 ft.more than we need and under we went, without even touching the tips of our antennas.

The Bertram caught up with us about 30 minutes later and awarded us with a giant wake. Nice boat driven by an inconsiderate slob, in our opinion.

We arrived at Portland Riverside and I did a terrible job of docking, but a bunch of guys were waiting and muscled our boat in while cheerfully blaming my poor docking job on the current. Since the river in Portland was swollen, muddy and filled with debris, we'll gladly take that explanation.

Next up, we winterize the engines and call the Summer 2014 boating season to a close.

We going to do some serious work to our starboard engine over the next month and we'll keep a video record of that. Hopefully, that will be interesting enough to keep some of our readers awake.

Monday, October 20, 2014

Frances recuperiates as we count down to departure

For all of those who asked about her, Frances is doing fine. Her left eye is healing nicely and she has started to regain her vision in that eye. She has a few more days in her special chair and then she'll be able move around more and not have to look down at the floor all the time.

With Frances resting comfortably (with a special mirror that allows her to see the TV), Bill went to the boat on Saturday. Most of the A-Dock summer crew was there, intent on doing the same thing we were: unloading all the stuff that had to be off for winter. It's still amazing how much there is, but who cares? It was a great summer and Frances was able, once again, to spend that time on our boat.

During all this time Pooka our boat cat has been visiting the Pappadopulas Inn and Spa. That's how we think of Pooka's visit with our friends Kim and Mike. Bill's elderly black cat would never tolerate another cat in her house, so Pooka is visiting Kim and Mike and will be home soon, we hope.

Good pictures from Mike and Kim:

Our plan is to leave Norwich next Saturday, October 25, and head to Portland Connecticut for winter storage. Our friend John (who helped us pick the boat up when we first brought it back from Long Island five years ago), has offered to join us. Frances won't be along for this cruise but John's assistance will be much appreciated.

We hope the weather will be good and we'll be watching it as the week unfolds.

We shot some video on Saturday. It won't mean much to most of those who see it on You Tube but it means something to us and we hope to our dockmates who we will miss over the winter.

Sunday, October 12, 2014

Guess we're not leaving for a while

Frances and Pooka were enjoying their last few weeks on the boat before leaving for winter storage when Frances had trouble with her left eye. She visited one the the immediate care facilities in the area and they sent her to an Ophthalmologist. He determined that she had a detached retina and that immediate surgery was required.

Luckily, she could see well enough to get to my (Bill's) house. Surgery was arranged for Thursday morning at Hartford Hospital and in the meantime, Frances, using her skills as a Business Analyst, took over and made all of the arrangements including a special chair that she would have to use while recuperating.

Pooka, the boat cat, needed a temporary home (since Bill has a cat with low tolerance for fur-covered visitors) and our dock mates Kim and Mike offered to host Pooka for a fall vacation. Kim and Mike love Pooka as much as we do and Pooka had no trouble making himself at home at their house.

We arrived at Hartford Hospital on 8 am on Thursday morning and after an hour's worth of processing, we met the surgeon who, incidentally, was great. Frances was understandably scared at the prospect of having her eye cut open but the staff assured her it was "minor surgery." Perhaps so, but it was still not a fun thing for her to go through.

The process for repairing a detached retina is interesting, if not a tad inconvenient. The surgeon inserts a gas-filled "balloon," that forces the retina back into position. Over time, the "balloon" dissolves, leaving the retina back in place. However, during the recovery period, Frances would have to look down - as in looking down at the floor - most of the time and that time could be a week or more.

To accomplish this, Frances is using a chair designed expressly for this purpose. Yes, she can take a break once in a while, but most of the time she has to be here.

She can read, but that's about all. At night, we rig a cushion on her bed so that she sleeps face down for the night. Throughout all of this Frances has remained her old self. On Saturday night, we made chili and corn muffins. That is to say, Bill carefully executed as Frances directed, face down. Hey, it was a damned good dinner!

As we were writing this blog post, Frances appeared to have her picture taken to let everyone know she's OK.

She's holding what she calls her night-time Binky, the cushion she has to sleep on to keep her face looking down. She's been very good about this and we hope that next Tuesday, when the doctor checks her again, that she will have made some progress.

In the meantime, special eye drops have to be used three times a day. Organized as ever, Frances has them lined up and checked off.

At this point, all we can do is follow the doctor's directions and wait for that eye to heal. But, Pooka is fine, the boat is fine and Frances is is in great spirits. Soon, we hope, we'll take our last cruise of the year.

The biggest boating rule is, "Keeping a proper lookout." It wouldn't be boating for us if Frances wasn't there to help us stay on course. Hopefully soon, she'll be back on the bridge.

Luckily, she could see well enough to get to my (Bill's) house. Surgery was arranged for Thursday morning at Hartford Hospital and in the meantime, Frances, using her skills as a Business Analyst, took over and made all of the arrangements including a special chair that she would have to use while recuperating.

Pooka, the boat cat, needed a temporary home (since Bill has a cat with low tolerance for fur-covered visitors) and our dock mates Kim and Mike offered to host Pooka for a fall vacation. Kim and Mike love Pooka as much as we do and Pooka had no trouble making himself at home at their house.

Pooka with his Godmother, Kim

We arrived at Hartford Hospital on 8 am on Thursday morning and after an hour's worth of processing, we met the surgeon who, incidentally, was great. Frances was understandably scared at the prospect of having her eye cut open but the staff assured her it was "minor surgery." Perhaps so, but it was still not a fun thing for her to go through.

The process for repairing a detached retina is interesting, if not a tad inconvenient. The surgeon inserts a gas-filled "balloon," that forces the retina back into position. Over time, the "balloon" dissolves, leaving the retina back in place. However, during the recovery period, Frances would have to look down - as in looking down at the floor - most of the time and that time could be a week or more.

To accomplish this, Frances is using a chair designed expressly for this purpose. Yes, she can take a break once in a while, but most of the time she has to be here.

She can read, but that's about all. At night, we rig a cushion on her bed so that she sleeps face down for the night. Throughout all of this Frances has remained her old self. On Saturday night, we made chili and corn muffins. That is to say, Bill carefully executed as Frances directed, face down. Hey, it was a damned good dinner!

As we were writing this blog post, Frances appeared to have her picture taken to let everyone know she's OK.

She's holding what she calls her night-time Binky, the cushion she has to sleep on to keep her face looking down. She's been very good about this and we hope that next Tuesday, when the doctor checks her again, that she will have made some progress.

In the meantime, special eye drops have to be used three times a day. Organized as ever, Frances has them lined up and checked off.

At this point, all we can do is follow the doctor's directions and wait for that eye to heal. But, Pooka is fine, the boat is fine and Frances is is in great spirits. Soon, we hope, we'll take our last cruise of the year.

The biggest boating rule is, "Keeping a proper lookout." It wouldn't be boating for us if Frances wasn't there to help us stay on course. Hopefully soon, she'll be back on the bridge.

Subscribe to:

Posts (Atom)