After the insurance claim and the subsequent cleanup were behind us, we did visit the boat a couple of times just to do boring stuff like cleaning and covering the furniture. Of course, we also made a winter boat list.

During another visit, we removed the starter from the starboard engine and took it to Joe's Auto Electric, which is nearby. (Joe's father rebuilt a boat alternator for use about 25 years ago.) The starboard starter worked OK, but not as well as the port one, which Joe's rebuilt several years ago. Just seemed to us like prudent maintenance. They know the starter is from a boat so we don't expect it back any time soon. No pics of the starter removal but we'll shoot some when we put it back in.

Making the trim tabs functional

Another item on the winter boat list is to get the trim tabs working. They did work at one time but very slowly. Recently they stopped altogether and although the boat runs fine with the tabs fully retracted, it would be nice to know that they do work.We'll shoot some pictures of what we've been doing next weekend. So far, we've limited our tab work to disconnecting the hydraulic cylinders from the tabs themselves. That allowed us to pull the tabs all the way down and apply several coats of paint remover. Scraping off many coats of bottom paint (not put there by us) takes a long time but it eventually works. We're close to completing the top of the starboard tab and next weekend, we'll try cleaning off the bottom.

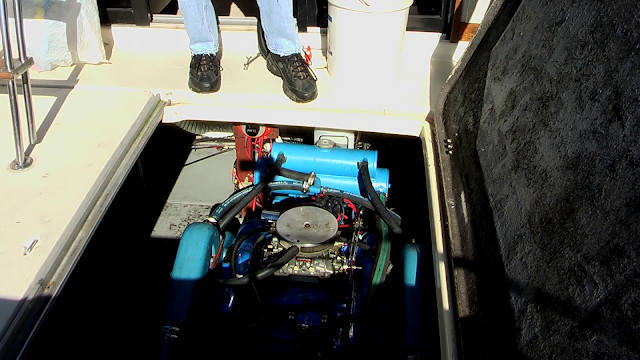

With both tabs disconnected from the rams, we tried applying some power to see if either of the rams extended. They didn't, although the pump was drawing some current. This may be as simple as filling the pump with ATF but that's a long shot. On a boat, the simple fix is fairly rare and in this case the pump is down there where the sun never shines so we have a feeling that this will turn into a true winter boat project. In other words, spend money.

Cold weather

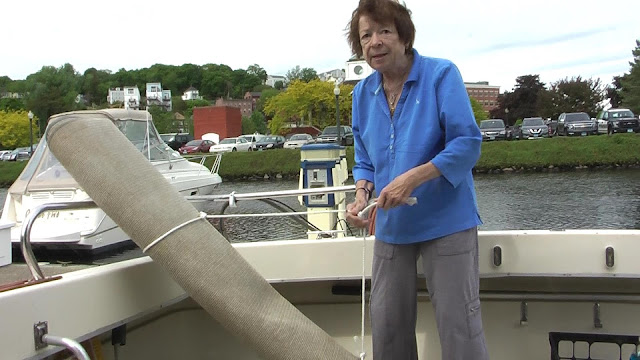

We've gotten our first taste of really cold weather. Last weekend, we went to the boat full of good intentions but the cabin temp was 28 degrees and after an hour of charging the batteries with our little cabin heater on, it had risen to 30. We gave up and went home. No fun working when you can't feel your fingers.The cold weather is tough on Francis but she has compensated nicely by redecorating parts of our house. She can't get an appointment with a specialist until late January but with any luck (and some decent medical care) she'll be back to heaving a bow line next spring.

A shoutout to Bill Moser

Thanks, Bill, for reminding us that we've fallen behind on blog posts. Yes, we're still alive and kicking and looking forward to the days getting longer and our boat "to-do" list getting shorter. Happy holidays to you from both of us.