Except for one little annoying detail.

As you can see, the front window cover is on and the boat is about ready to head off for the summer. She's washed but the real polishing (if you can polish a 33 year old boat) will have to take place in Norwich. Surprising how the inflatable filled out once it got back in the sun.

Even the chart plotter worked. Nice to know we're where we thought we were.

But the real issue is fixing whatever is causing our starboard ignition coils to fail. We recounted the history here but we'll do it again if you haven't read it before.

We replaced the old Chrysler distributors with Mallory YLM (magnetic) distributors two years ago. After that, we discovered that the regulator on our starboard engine alternator had failed and that alternator was putting out in excess of 17 volts DC. That high voltage took out the VHF radio on our fly bridge and our Sony stereo in the cabin. We subsequently replaced the alternator.

Ever since then, we've had failures of the coil on the starboard engine, usually after an hour or so at cruising speed. Change the coil and the engine runs perfectly, for a while. Time to fix this.

We went through the entire ignition system on the starboard engine and replaced everything. That included the coil, distributor cap, and rotor. All that was left was the ignition module in the Mallory YLM distributor. Our hope was that it had been damaged and was causing our regular coil failure..

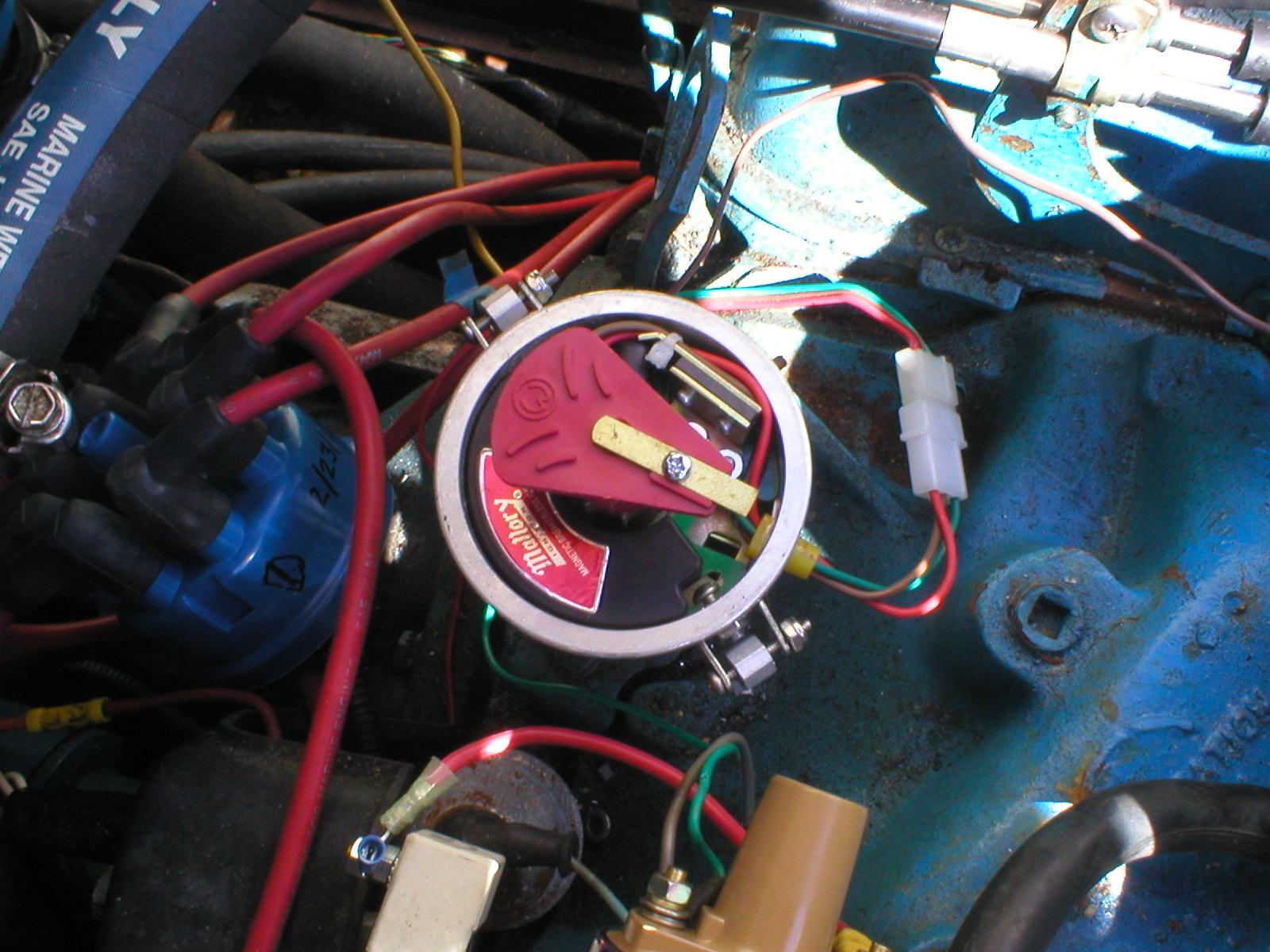

Today, we tackled that replacement. Not easy, as it turns out. The ignition module inside the distributor is held in place by the heads of the machine screws that also hold the distributor cap clips. Here's what the old one looked like in the distributor and after we removed it.

We won't bore you with all the little problems we had to deal with to get this out or to install the new module or to set the gap with a piece of (Mallory supplied) Mylar that was exactly .047". Forget even trying to set the gap that close. When we finished, the gap was much wider than that but the engine started instantly and idled very smoothly..

Here's the distributor with the new ignition module installed. We had to re-engineer the way the distributor cap is held in place. There are now 6-32 machine screws with stop nuts rather than cheap-o pieces of aluminum rod holding the two distributor caps in place..

With all that done, we headed up to the cabin the start the starboard engine, which hadn't been run since last weekend. We gave her one pump of the throttle to set the choke, turned the key and off she went and the settled into a nice 600 rpm idle. This was the engine that always needed to be cranked a few times to start.

Maybe we're on to something here. Sure hope to.

But did we really fix this problem?

Saturday evening, we kept turning this supposed repair over and over in our head. We don't really know if we have fixed whatever was killing the starboard ignition coils. Yes, we replaced everything in the starboard ignition system but without taking a 35 mile cruise, we really don't know.

We have an identical engine on the port side with exactly the same ignition parts that never, ever fails. We read back over the repair records, which could be titled, "So Many Coils and So Little Time." What is different about the starboard engine?

The obvious answer is that the starboard engine had an alternator regulator failure that damaged some electronic components and the port engine did not. That's the thinking that lead us to the replacement of the starboard ignition module in the first place.

On Sunday, after taking care of some business and then mowing the grass, we drove back down to the boat and puttered around, checking the fluid levels in the engines, transmissions and v-drives. Then, still thinking about the differences between the ignitions on the two engines, we took the distributor cap off the port (reliable) engine and used our piece of .047" Mylar to check the gap between what Mallory calls the reductor and the magnetic pickup. It was a very tight fit when we inserted our Mylar strip.

We thought back to what that same measurement had been on the starboard distributor before we removed the old ignition module. It was much wider, perhaps 2-3 times wider than .047 and that was how it was when we originally took that new distributor out of the box two years ago. Thinking that was okay, we set the gap quite a lot wider than .047" when we installed the new ignition module. (Setting this gap isn't easy.) That was sloppy and we went back to the starboard distributor and after a number of attempts, set it at a very tight .047, just like the reliable old port engine.

With the new gap, the starboard engine started immediately and ran up through 3,000 rpm without an issue.

We know. Reading this post is like watching paint dry

We understand how boring all of this is, but the blog gives us a valuable history as to what we have done to fix this recurring problem. Soon, we'll cast off and head for Norwich for the summer. That cruise will tell the tale about whether or not we have found this elusive problem.

But just to make sure we get there, we'll have a couple of extra coils on board.

No comments:

Post a Comment